It’s a supply chain risk that is often overlooked. While forced labour and child labour remain at the forefront of salient issues threatening supply chain integrity and responsible sourcing, excessive working hours is another all-too common violation that is equally harmful to a supply chain’s health.

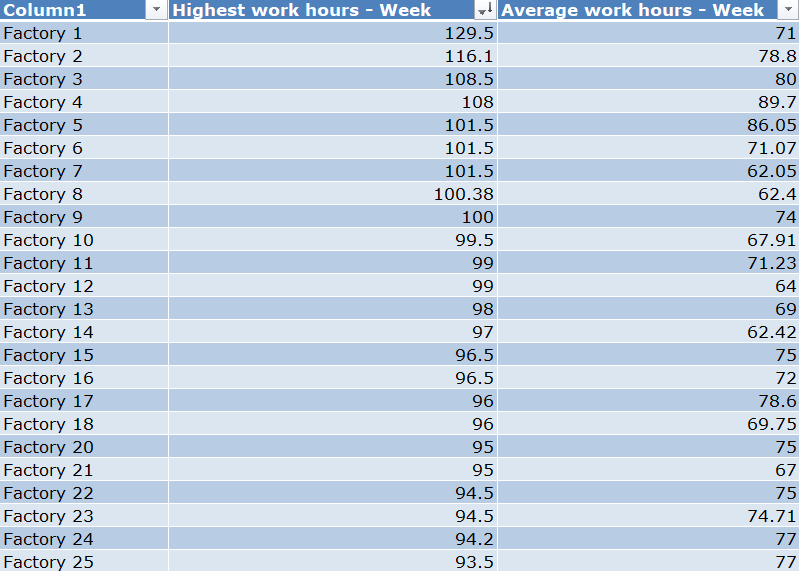

Two of the metrics LRQA assesses from factories and sites through our supply chain due diligence platform EiQ are the average amount of time that workers spend in a factory continuously working and the longest period of time a worker has been continuously working. The International Labour Organisation (ILO) says excessive working hours means regularly working more than 48 hours per week – but what if a factory’s employees are clocking say, 129 hours in a week? This is a real statistic from a recent risk assessment conducted on factories for a large Western retail chain.

It is common to see overtime violations in factories – with extreme cases being 60 to 80 hours a week, as peak production seasons are high. But the supply chain sites assessed below showed at least 25 different factories where employees worked more than 90, even more than 100 hours in one week.

LRQA assessment data, 2024.

LRQA assessment data, 2024.

What is this data telling us? Risk mitigation strategies are still falling short. And risk remediation cannot only apply to forced labour and child labour instances – but to all transgressions which violate workers’ basic rights.

Markets at high risk for excessive working hours

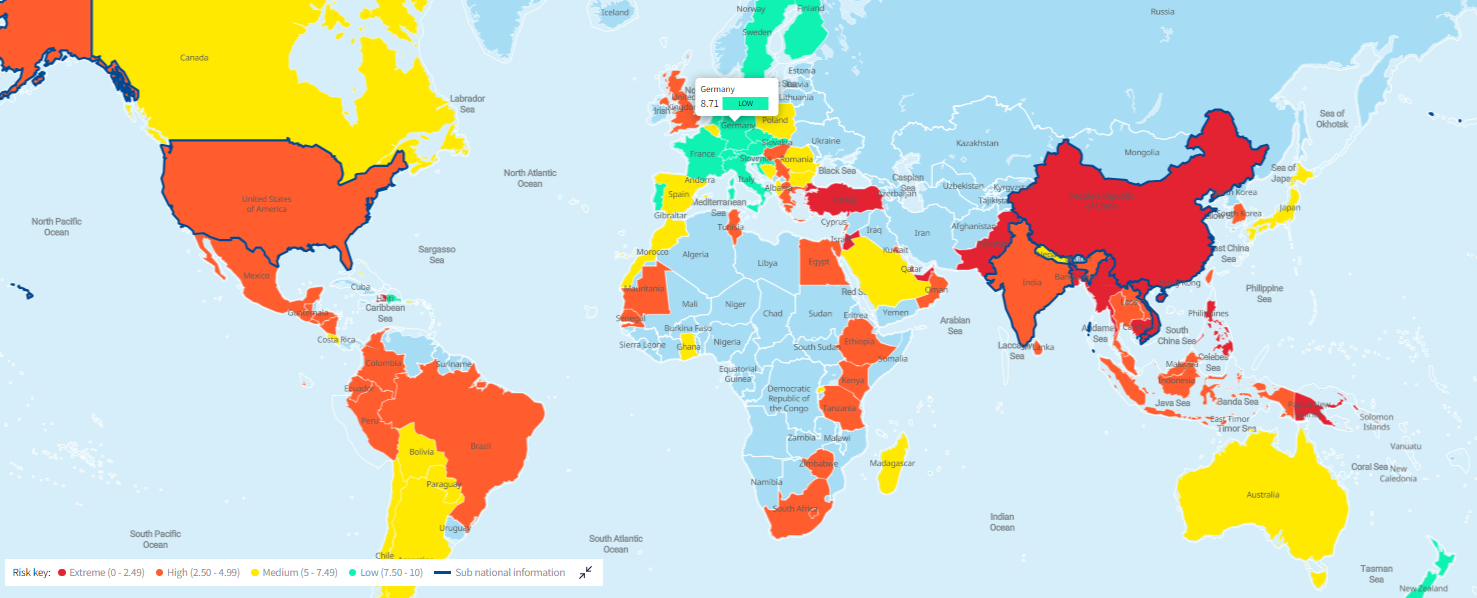

Our supply chain ESG global risk analysis shows the sourcing markets with the highest risk exposure to working hour violations. In 2024, China showed some of the most extreme levels of risk for working hour issues on sites, followed by other key sourcing regions such as Bangladesh, Turkey, and Pakistan.

Global risk heat map, working hours, 2024, EiQ.

Global risk heat map, working hours, 2024, EiQ.

Excessive working hours are increasingly being linked to health and safety issues among workers, and in 2016, the ILO estimated that nearly 40% of 1.9 million work-related deaths could be attributed to long working hours.

Owning due diligence, improving risk management

It's the responsibility of organisations to conduct further due diligence on their upstream activities and understand where violations may be occurring at every link of their supply chain. Broadening the focus on all critical labour issues and ensuring these critical violations are being prioritised and mitigated are essential to maintain regulatory compliance and protect workers' rights connected to their operations.

In the era of Assurance 4.0, what we coin the new era of risk management, we at LRQA recognise the pivotal role of data and analytics in managing risk, enhancing your business performance and creating a competitive advantage. Our EiQ platform is driven by analytics capabilities which can be applied to address current and future risks within your operations and supply chain.

EiQ uses LRQA’s unique, proprietary data to enable end-to-end supply chain ESG due diligence. The platform also helps you understand your supply chain risks and informs us on how best to develop highly tailored solutions aligned to your business strategy. Through our solutions-based approach, we can take you beyond compliance and enable you to drive sustainable growth, by assuring your data and management systems, achieving product integrity, and sourcing responsibly.

Get a free demo of EiQ to understand your supply chain’s ESG risk exposure.