So you're finally getting to grips with understanding the risks in your supply chain and learning to identify where the problem areas lie. While this is a positive step in improving your supply chain due diligence, it is only the tip of the iceberg. New supply chain laws require businesses to not only know and communicate the risks in their supply chains, but to also demonstrate the steps they are taking to mitigate and remediate those risks.

Forced labour, child labour, poor health and safety conditions for workers and the impacts of climate change continue to threaten the integrity of responsible sourcing programmes and often are hidden throughout the supply chains of the world’s most beloved brands and retailers. So, while knowing the risks among your suppliers and various supply chain partners is crucial, businesses must go a step further and understand how to ensure these risks do not become commonplace among their supply chain operations.

Shifting to a fit-for-purpose approach

New technologies and improved datasets allow companies to have a more granular view of the risks in their supply chains and to better understand their individual needs. Each supply chain’s risks are unique, and each area of your supplier base will most likely require different levels of attention and resource allocation.

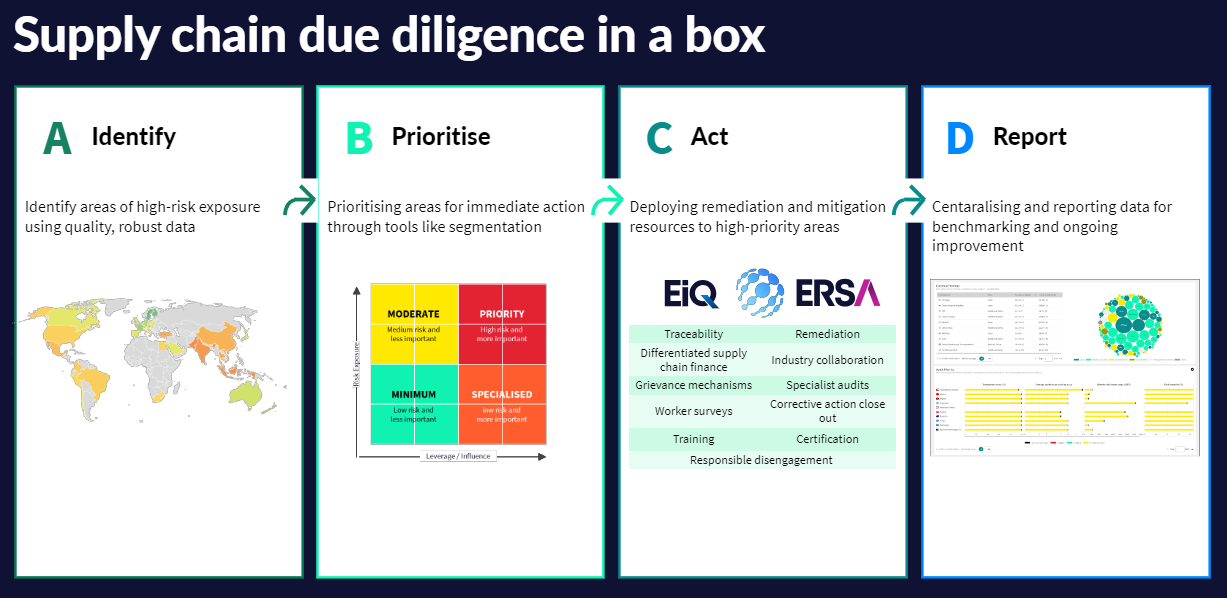

Using EiQ, we support each step of the due diligence process based on the needs of your individual supply chain.

- Identify: It is essential to get a holistic view of your ‘your chain of activities,’ or each step of the value chain, and to understand the coinciding risk exposure for each. This will mean centralising your supplier audit data and leveraging a wider dataset to identify the inherent risk of the regions you are operating in as well as the production risks associated with your commodities. The identification process goes beyond audits to include other data points, such as adverse media incidents associated with suppliers to identify risk trends and potential future risks.

- Prioritise: Once a more comprehensive overview of your risks has been developed, we can then support with mapping out the high priority areas, typically the areas with highest risk exposure. This will help with deploying mitigation efforts to areas that require immediate attention, shifting away from the standard one-size-fits-all approach and understanding where the greatest need is and where the greatest impact can be achieved.

- Act: Many companies tend to approach the ‘act’ step too broadly, oftentimes deploying self-assessment questionnaires (SAQs) to their entire vendor base or only auditing their Tier 1 suppliers. This is where businesses should shift to a more tailored approach. When the highest risk hotspots are identified among their suppliers and vendors, they can allocate resources more effectively. This could mean auditing high-risk suppliers more regularly and thoroughly, as well as conducting SAQs. It could also include deploying supplier engagement through digital training courses, implementing Corrective Action Plans (CAPs) when audit violations are uncovered, or integrating grievance mechanisms to ensure worker issues are heard and addressed.

- Report: Through data consolidation and ongoing monitoring and reporting, businesses can better benchmark and monitor the progress of their risk management and remediation.

For responsible sourcing managers, the need for improved supply chain due diligence is two-fold. On one side, there is the need to comply with regulations and to adhere to increasing reporting requirements as a civil liability. On the other, there is the moral responsibility to limit the adverse impacts from your supply chain operations in order to safeguard human rights, limit adverse environmental impacts, and ensure business integrity is maintained. Both are crucial to maintaining responsible sourcing integrity and improving business-driven sustainability.

Get a free demo of EiQ today and learn more about how our data insights can support your supply chain due diligence.